Electroplating is a metal plating process that involves immersing a part or object in an electrolytic bath containing metal ions. The objective is to deposit a layer of metal on the surface of the object, improving its resistance, aesthetics or other properties. This is our speciality!

See below some of the baths that are performed by us.

Copper bath

Copper is often used as a base bath to prepare the surface before applying other metals. It can also be used as a top coat to provide a glossy finish or corrosion protection.

Nickel bath

Nickel is a metal widely used in electroplating. It offers good corrosion resistance, hardness and magnetic properties. The nickel plating can be used as a base coat or a top coat, depending on specific needs. Depending on the purpose of processing the part, the nickel bath can be (i) semi bright, (ii) bright or (iii) satiny.

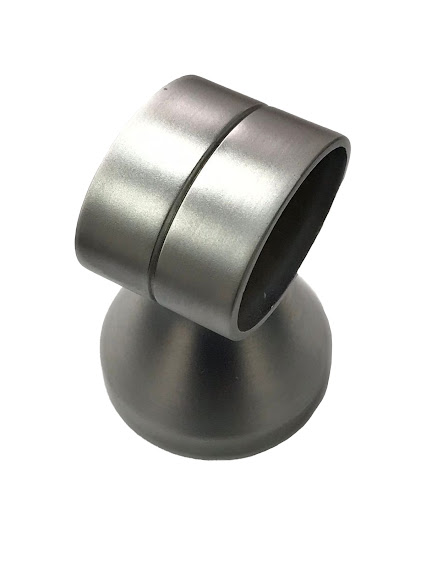

Chrome Bath

Chromium is known for its corrosion resistance, durability and decorative properties. It is often used as a top coat to give a glossy, mirror finish to automotive parts, housewares, bathroom accessories, and more. The chrome bath can be Brushed, when the intention is to obtain a surface with a more matte texture, instead of the mirrored shine typical of conventional chrome or else, it can be satiny which produces a more matte finish.

Now when the subject is a surface of high brightness and mirroring, there is clearly a treatment of bright chrome, but if the intention is an intermediate finish between bright chrome and matte chrome, the solution in processing is chrome semi bright.

Gold-Plated

Gold is a noble metal that offers excellent corrosion resistance and has a unique aesthetic appeal. It is commonly used in high-quality jewelry, watches and electronic components. However, they have also often been used for a more luxurious finish on household items such as door handles, for example.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the "Functional" category. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies are used to store the user consent for the cookies in the "Necessary" category. |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |